Abrasion Resistance

The ability to resist wear from rubbing which contributes to a fabric's durability.

back to top

Absorbency

The ability to take in moisture. Fibers able to absorb water easily are called hydrophilic fibers.

back to top

Acetate

A manufactured fiber in which the fiber-forming substance is cellulose acetate.

Favorable: Acetate has excellent draping qualities and has a luxurious hand. There are no pilling problems and very little static issues. It is also inexpensive.

Unfavorable: Acetate has poor strength and becomes 30 percent weaker when wet. Because of the poor wet strength it should not be washed but dry cleaned. Excessive shrinkage may occur from the heat.

back to top

Antimicrobial Fabrics

Growth of bacteria and fungi in textile fabrics are usually undesirable. Chemicals that prevent growth of bacteria and fungi are referred to as antimicrobial agents.

back to top

Calendering

Consists of passing the fabric between rolls under pressure. The luster of the fabric is increased because the yarns are flattened making the fabric surface smoother and better able to reflect light. Adding moisture to the fabric and heating the calendar rolls accentuate the effects of calendering

back to top

Cotton

A seed fiber attached to the seed of the cotton plant. It is the most widely used fiber in the world. Certain species of cotton such as American Pima or Egyptian have an extra-long staple length. The extra long staple provides greater strength, more luster, and a silky hand as compared to traditional cotton staple. Since cotton is a plant fiber, it is composed mainly of cellulose.

Favorable: Cotton fabrics can be mercerized to enhance strength and luster. The fiber itself has good strength and absorbs moisture quickly. In addition it dries quickly. Quick drying provides a cooling effect which makes cotton a good fiber for hot weather. Cotton is washable and dry cleanable. In addition, it does not pill or have static problems.

Unfavorable: Cotton fibers lack elasticity and resiliency. Mildew can form on cotton.

back to top

Cross Dyeing

This is a special type of dyeing in which a fabric with two or more fiber types that have different dyeing qualities is dyed in a single bath containing two different classes of dyes. Each class of dye colors only one type of fiber. Two different colors can be dyed in one dye bath. Our style Wilmont is cross dyed.

back to top

Denier

The weight per unit length of a fiber measured in grams per 900 meters. Lower numbers represent finer or smaller sizes. Higher numbers represent coarser sizes.

back to top

Dobby Pattern

A design which contains simple geometric forms or motifs. These designs are made by a regular loom referred to as a dobby loom. This loom can control up to thirty-two harnesses to create a design.

back to top

Fill Yarns

Yarns that run widthwise across the fabric.

back to top

Greige Goods

Undyed or unprocessed fabric.

back to top

Hand

The way a fiber feels when handled. The hand of the fiber is affected by its shape, surface, and configuration.

back to top

Jacquard

A design which contains very detailed, intricate motifs. A special loom is used and usually has no harnesses. Since there are no harnesses any combination of yarns can be raised or lowered to produce the design. This loom operates more slowly than a dobby loom.

back to top

Luster

Refers to the light reflected from a surface. Various characteristics of a fiber will affect the amount of luster produced. A fabric with a smooth surface, less crimp, and long fiber length will have increased light reflection.

back to top

Pilling

The formation of short or broken fibers on the surface of a fabric which are tangled together in the shape of a tiny ball called a pill. These pills are formed when the ends of a fiber break from the surface due to wear. Strong fibers like polyester tend to hold pills to the fabric surface which are unsightly.

back to top

Polyester

A manufactured fiber in which the fiber forming substance is any long-chain synthetic polymer composed of at least 85 percent by weight of ester. The fiber has a rod-like shape with a smooth surface.

Favorable: Polyester is a medium weight fiber with very good strength and abrasion resistance. It can be washed or dry cleaned.

Unfavorable: It is difficult to get wet and thus stain removal is more of a challenge. Static and pilling are also major problems. In addition oily substances have an affinity for polyester.

back to top

Repellent Finishes

Repellency is attained by limiting the wet-ability of the fabric. Repellent finishes in contrast to waterproof finishes only modify the surface of fibers and do not block the interstices. Therefore, the fabric remains porous to air and water vapor.

back to top

Selvage

Lengthwise edge of a fabric. It is usually ¼ to ½ inch wide and exists on both edges of the cloth. The main purpose of the selvage is to ensure the edge of the fabric will not tear when the cloth is undergoing stresses and strains of the finishing process.

back to top

Silk

A continuous strand of two filaments bonded together, forming the cocoon of the silk worm. Spun silk yarn is made of short fibers from pierced cocoons. Silk is composed mainly of protein because it is an animal fiber.

Favorable: The fiber has superb draping qualities and a luxurious hand. Silk does not pill and static issues are rare. Even though silk can be washed, it is best to dry clean due to the dye used in coloring.

Unfavorable: Silk only has fair abrasion resistance and loses strength when wet. It is expensive and degrades over time.

back to top

Soil Release Finishes

Chemical wet finishes in fabrics that permit relatively easy removal of soils. Since polyester cannot become thoroughly “wetted” in laundering, stains cannot be easily removed. Soil release finishes make the fiber more absorbent permitting better wet-ability for improved soil removal.

back to top

Strength

The ability of fibers to resist stress. Fiber strength is usually expressed as tensility. Fibers such as polyester are strong while acetate and acrylic are weak.

back to top

Thread Count

Total number of threads running in both directions per square inch in a woven fabric.

back to top

Warp Yarns

Yarns that run parallel to the selvage.

back to top

Wool

The fiber that forms the covering of sheep. There are about 200 different types of wool fiber of various grades. The best quality wool comes from the sides and shoulder of the sheep. Fleece or clipped wool is wool shorn from live sheep. Lambs wool is taken from a sheep of less than one year and is very soft. Wool is mainly composed of protein because it is an animal fiber.

Favorable: Wool has a good resiliency when dry. Wrinkles will hang out of a wool fabric if hung in a moist environment. It drapes well and has little problems with static. Because of it’s natural crimp the yarns do not pack together which creates excellent insulation properties.

Unfavorable: Wool is a weak fiber and only fair in resisting abrasion. It has poor luster and loses 25 percent of its strength when wet. It is best to dry clean to prevent shrinkage.

back to top

Yarn Dyeing

After the cloth has been woven or knitted, the goods are dyed. This is the most common method of dyeing used.

back to top

What are the roll and case size yardage put ups?

The yardage on a roll is dependent on the weight of the fabric and the end market it is used for. Typically the following guide lines are used.

1. Cotton Prints 54 inches wide…60 yards per roll, 300 to 360 yards per case.

2. Polyester / Cotton Prints 54 inches wide…100 yards per roll, 500 to 600 yards per case.

3. Cubicle Curtain 72 inches wide…60 yards per roll for yarn dyed goods and 100 yards per roll for all other styles.

back to top

What is the lead time required?

Even though we try to anticipate your fabric requirements it is best to allow a three week lead time when ordering fabric that is produced domestically.

For imported fabric please allow an eight week lead time.

In many instances delivery will be shorter than this time period, but this provides a safeguard against unanticipated surges in demand on a particular pattern / color.

Our price schedule lists those styles which are imported.

back to top

Do all 100% polyester fabrics pass the various burn codes?

No, this is a popular misconception. Two of the most referenced burn codes in our industry are the NFPA 701 Small Scale (which is for the health care market) and the MVSS302 Code (which is for the RV market). Fabrics are not inherently fire retardant. Rather, chemistry is applied in either the yarn before it is extruded, in the dye process or when the goods are finished. The manner in which it is applied will determine its longevity and how it affects the finish of the goods to which it is applied.

back to top

What is a dye lot?

A dye lot is the yardage amount of a specific fabric that can be dyed at one time. This is determined by the dye equipment being used and the weight and width of the goods to be dyed. Dye lots can vary between 650 to 1650 yards. Even though computer kitchens are used to match colors each dye / production lot of a particular color will vary from the prior one.

back to top

What is the process to produce special colors on a print or woven fabric?

For special colors on a woven fabric we would require a standard to match for color. A lab dip will be produced on the fabric specified to provide a commercial match of the submitted shade. Once the lab dip is approved, a production lot can be dyed. Production lot sizes vary. They are based on the weight and dye process being used. Typically, they run between 650 and 1650 yards. Before running the production lot, we would require an order for the full production run. At the beginning of this process, we will advise the yardage commitment required.

For special colors on prints we would request color guidance to be used in the desired pattern. Prints can vary between 1 to 12 color placements. Thus it is beneficial to talk with one of our stylists to determine the color story you wish to achieve in a particular print. The frequency of screen placements will determine which color or colors will be predominant. Before printing a CAD will be submitted for approval. The approved CAD will be used as the color match standard for the print production. Print lots require a 3,000 yard minimum. Small production runs would incur a surcharge.

back to top

How can you determine if a fabric is crooked?

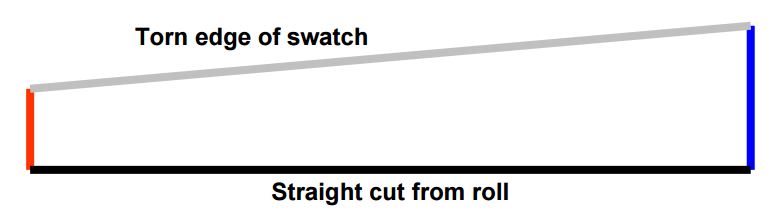

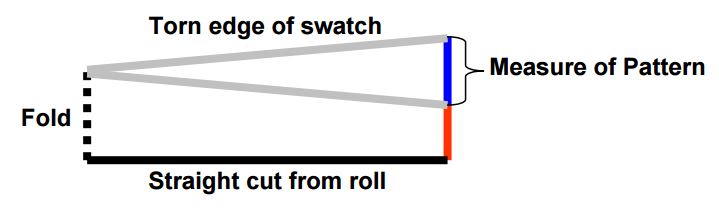

1. Make a straight cut from selvage to selvage of the fabric as it comes off the roll.

2. Advance the cloth about 1⁄2 yard.

3. Make a small cut on one selvage and tear the swatch across the width.

4. Fold the swatch in half. The difference between the lengths of the selvage is the bias of the cloth.

As a general rule, the tolerance for the bias is determined by the width of the fabric. For example,

the acceptable bias for 72 inch wide fabric is 2 1⁄2 inches industry wide. Our tolerance level is 1 1⁄2

inches.

back to top